Albertsons had three legacy systems built in the 1980s to collect, schedule, and process the orders from a network of stores to distribution

centers, warehouses, and DSD suppliers. Albertsons spent 18 months in the build vs buy study and could not find a product that could meet the

+98% business needs. At the same time, Albertsons did not have the in-house skills to develop a modern, cloud-native, highly scalable product.

Scoperetail partnered with Albertsons to build a new Cloud Native order management system (COSMOS) which went live in all 2200 stores

towards the end of 2019.

At Albertsons, we are very excited to announce the rollout of a new store order management system, COSMOS. Our strategic

partnership with Scope Retail System to build a highly scalable and robust platform leveraging the latest digital technology stack

continues to be strong. The team is very collaborative and always demonstrates flexibility and reliability. We look forward to

strengthening our association even further in the future.

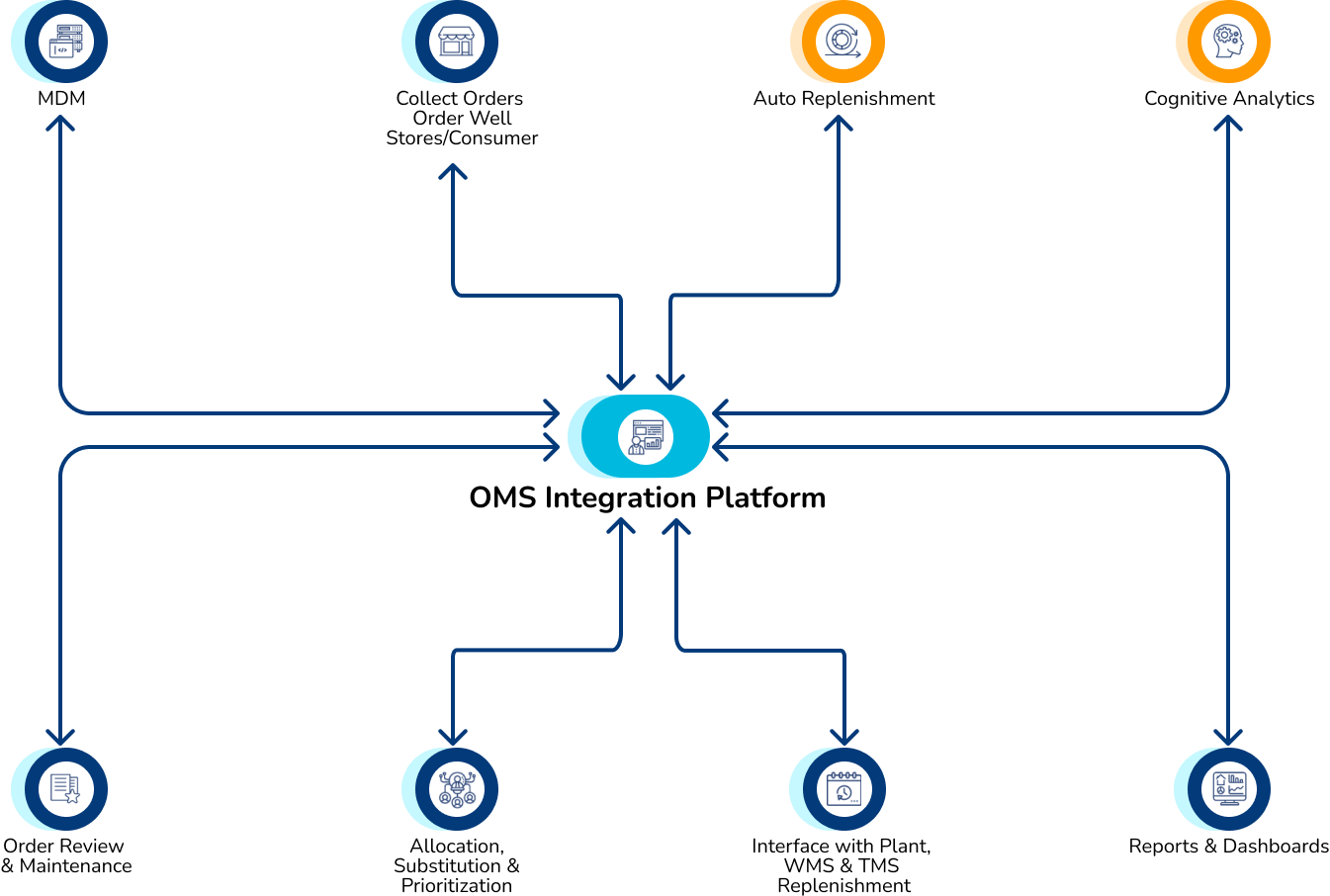

- A Micro-services architecture-based product, deployed in a cloud environment

- Uses advance techniques to perform auto replenishment and predictive analysis to supplement the orders

- Uses various algorithm for inventory allocation, prioritization, and substitution

- The rules engine allows the client to configure their business rules for their needs.

- Captures orders from various sources like Stores, eCommerce customers, manufacturing plants, 3PL, Manual orders to create Order Pool.

- Dynamically route orders to their source of supply for fulfillment by reducing lead time and cost.

- Simplified order monitoring with user friendly UI and custom reporting

- Easier schedule maintenance with more control for order release by a supplier

- Integrates with Warehouse & Transportation Management System

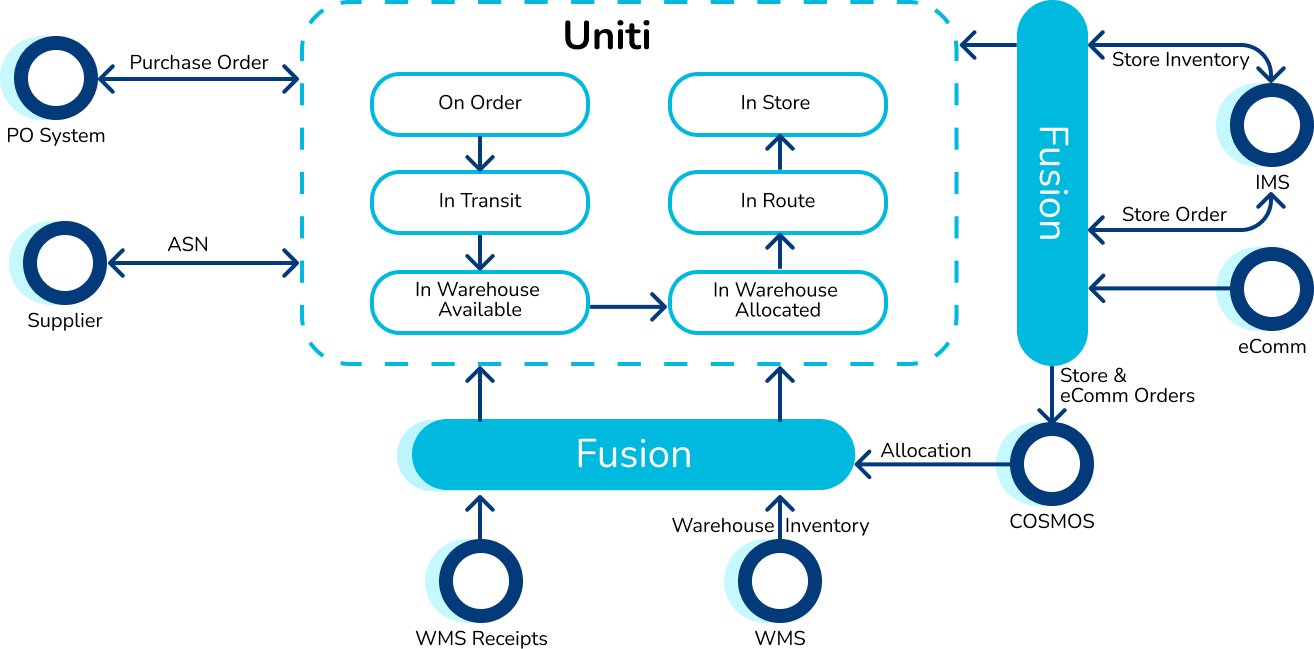

- Near Realtime Inventory Visibility and its state across the network

- Access to one inventory number and its state to make decisions across the channels, enabling growth in Ecomm business in Omni chanel world

- Visibility to Resident & Transactional Inventory

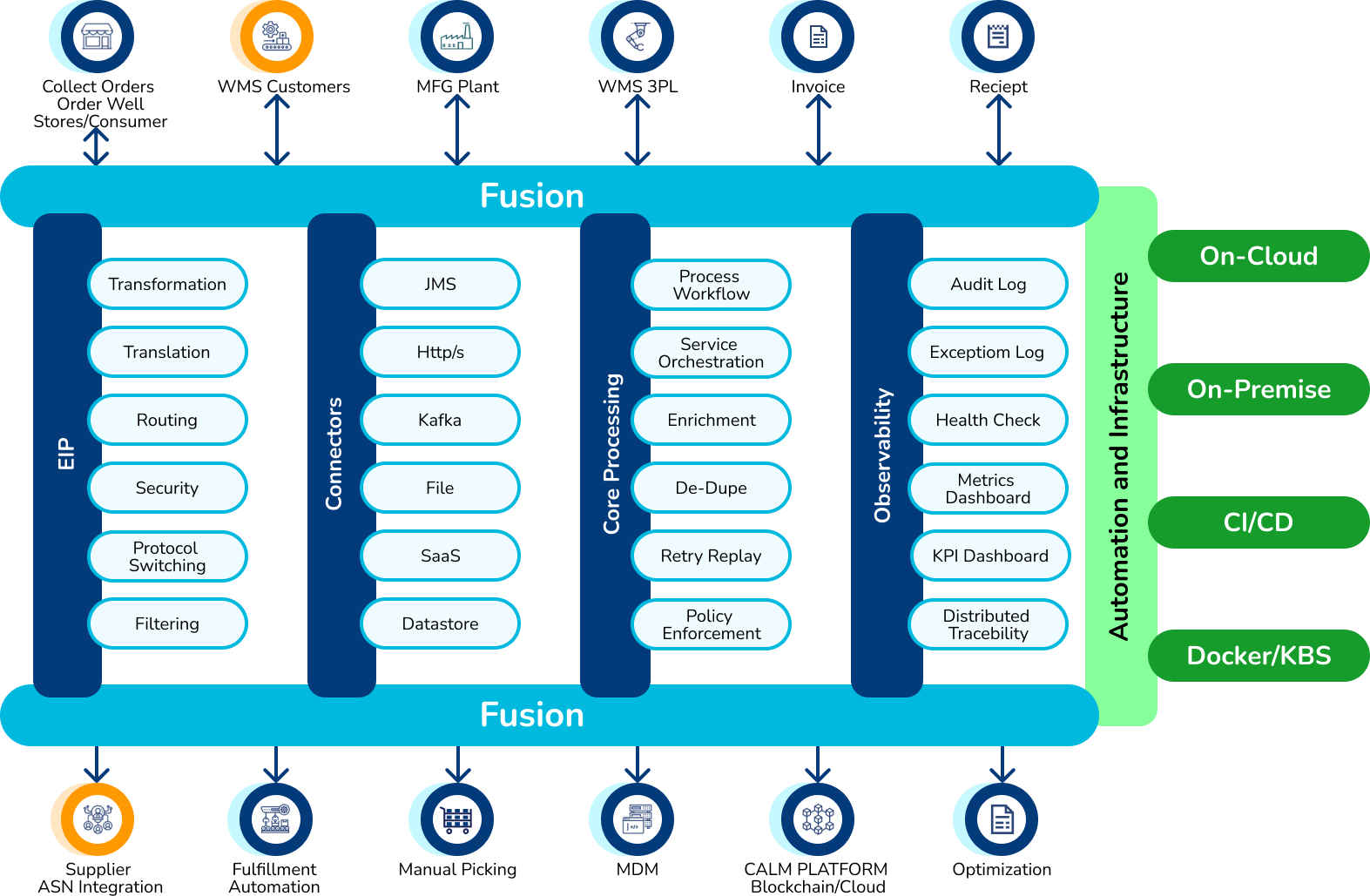

- Open standard integration platform

- Cloud Native and distributed Architecture

- Support for all Enterprise Integration Patterns

- Trusted by the world’s leading organizations

- Open Source under MIT licence

- A Microservice architecture based product, deployed in a Cloud environment

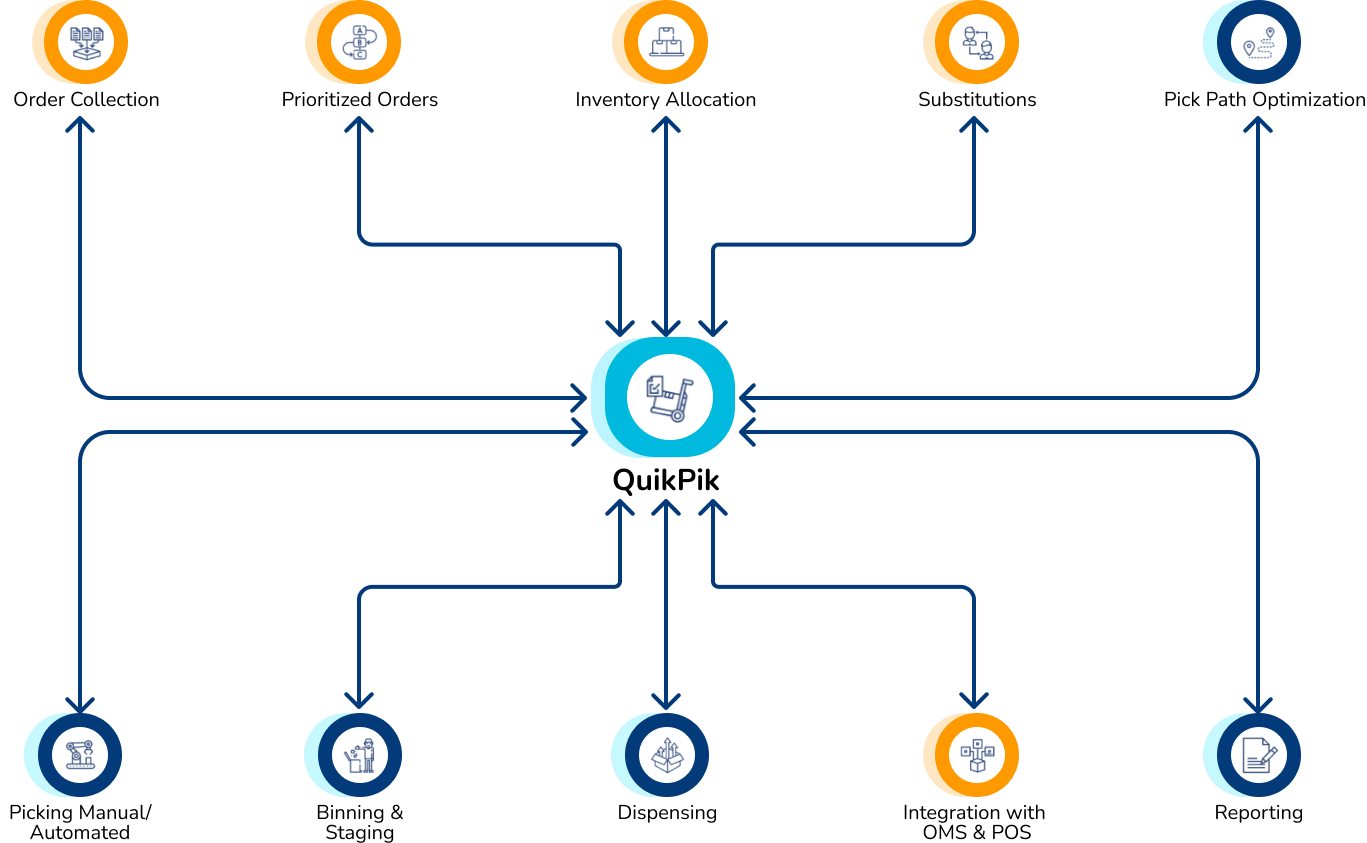

- Uses various algorithms for inventory allocation, prioritization and substitution

- Uses Proprietary developed OLCM (Order Life Cycle Manager) to control the cycle of an order through various status

- Uses advanced techniques to calculate how many totes/bags/cases are required to fulfill the orders with their sizes

- Rules engine allows client to configure business rules for their needs

- Integrates with OMS , Inventory Management System, Automated picking like robots, Dispensing, POS and Last Mile delivery system

- Simplified order monitoring with user friendly UI and custom reporting

- Prioritizes orders for picking based on delivery or pick up time

- AR and Voice Enabled picking

- Temperature zone specific picks and consolidation for dispensing

- Dynamically assigns orders to picker

- Supports Pick Path Optimization

- Supports single-order and multi-order picks

- Captures eCommerce orders from Order Management System

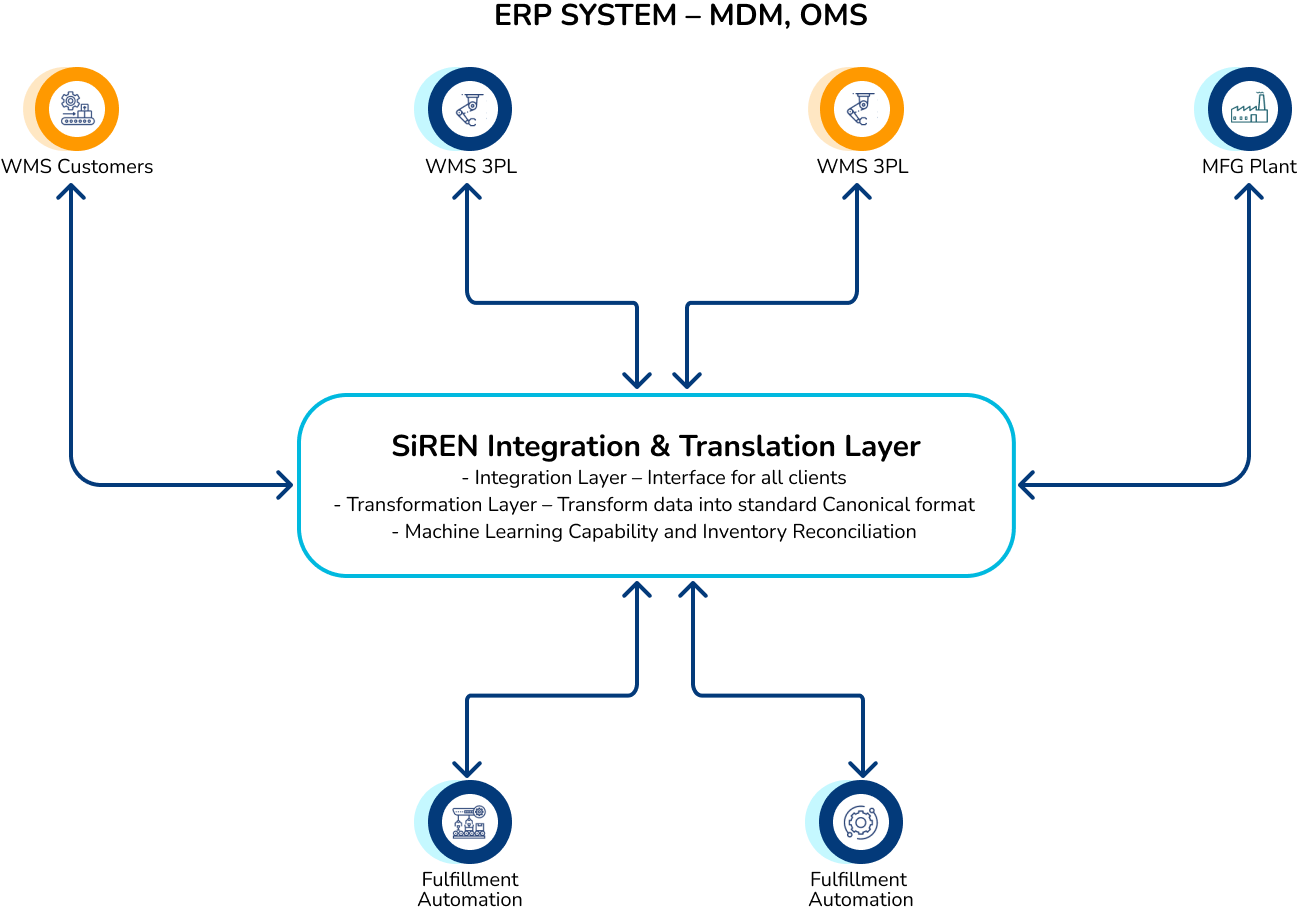

- SiREN - Scope Inventory Reconciliation

- SiREN is a generic Integration layer which gives flexibility to connect any robotics, AGV or WCS with fulfillment and manufacturing systems. It enables the inventory reconciliation between automation and fulfillment inventory systems.

- SiREN will also do automatic inventory reconciliation and will keep inventory in sync between WMS and Automation Module

- Automation vendor partners can focus on optimizing their software and let SiREN do the rest.

- Allows the customer to use any WMS. SiREN will take input from WMS in any format and converts into standard canonical format designed by automation vendor

- Simple and Fast. Reduction in integration time by almost 6-8 months. Estimated time to integrate is around 4-5 months

- Cost of Integration is considerably less than point to point solution

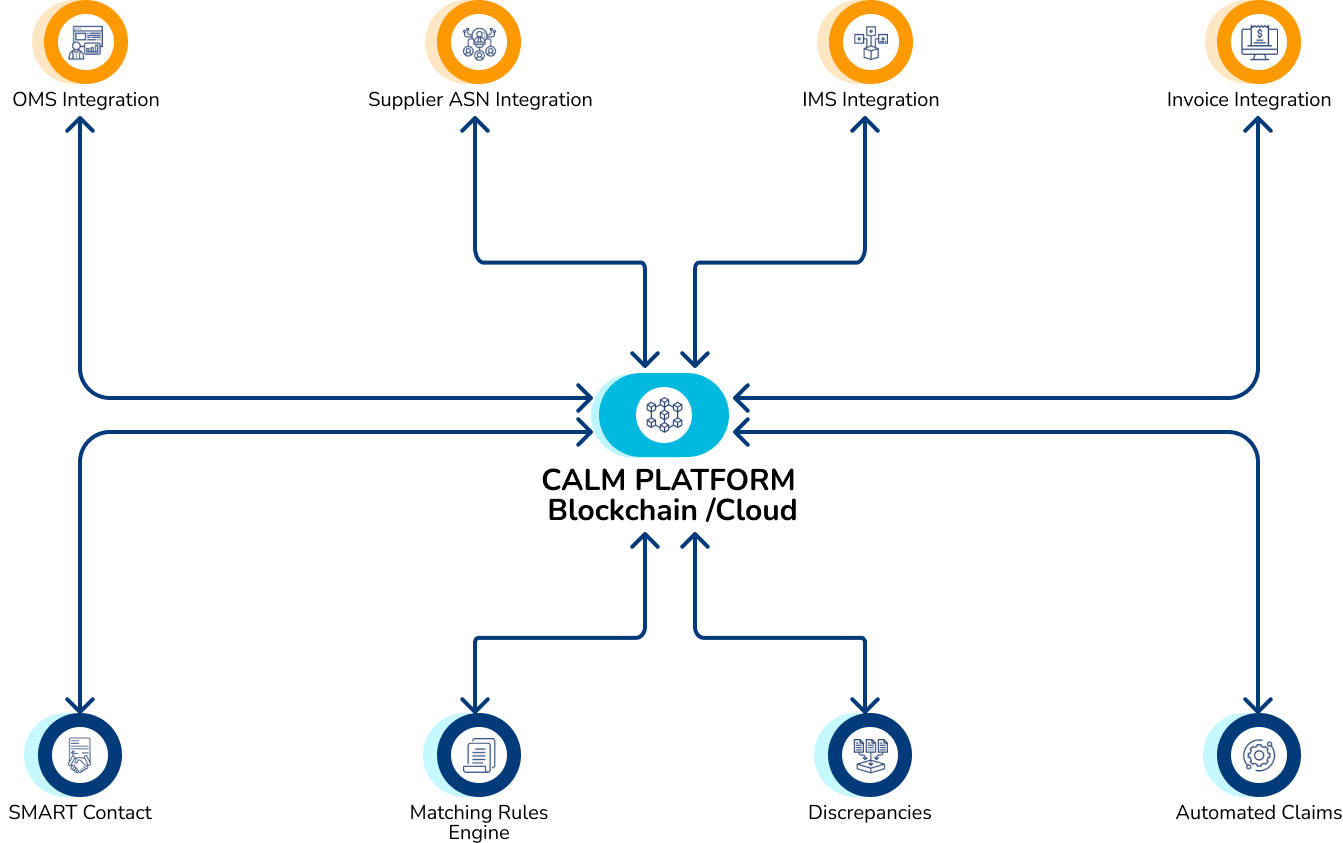

- Reconciliation between store orders, warehouse receiving’s, store receipts and vendor invoices.

- Initiate the Credit request to warehouse/supplier in case of discrepancy in quantity or price

- CALM can take input from any OMS, Supplier ASN, Supplier Invoice and Store Receiving System

- Modernized installation with blockchain technology or SaaS based model with cloud implementation

- Exclusive dashboard with summarized or detailed view of claims against supplier or warehouse

- Fully digitized - no manual invention or Digital matching of the records

- Quick processing of credit request and claims filing

- Cost of administering claims is considerably less than manual matching and filing of claims